TOOL TETHERING

An Easy 3 Step System to Tether Your Tools

It can be stressful being responsible for other people’s safety.

There are so many things to consider and variables to factor in. We understand the challenges you’re facing and want to take the worry out of one area: dropped objects.

Today, an increasing number of people are working at height. Your first priority will be fall protection and that’s certainly important. But we believe there needs to be an increased focus on dropped objects.

Why?

Because tools at height continue to be a major cause of workplace injuries and fatalities.

Luckily, there’s a simple solution to this problem:

Tool tethering.

We’re going to explain:

What tool tethering is

Why you should tether tools

How to tether tools with the 123 Tool Tethering System™️

Safety standards for tool tethering

International tool tethering regulations

Training for tool tethering

How to get started with your own policy

What is tool tethering?

Let’s start with the basics. Tool tethering is a way of preventing tools from falling or being dropped. It involves attaching tools to either the operative using them or, in the case of heavier tools, to a fixed anchor point. It doesn’t need to be complicated, but any system does need to be safely designed and the tool lanyards fit for purpose.

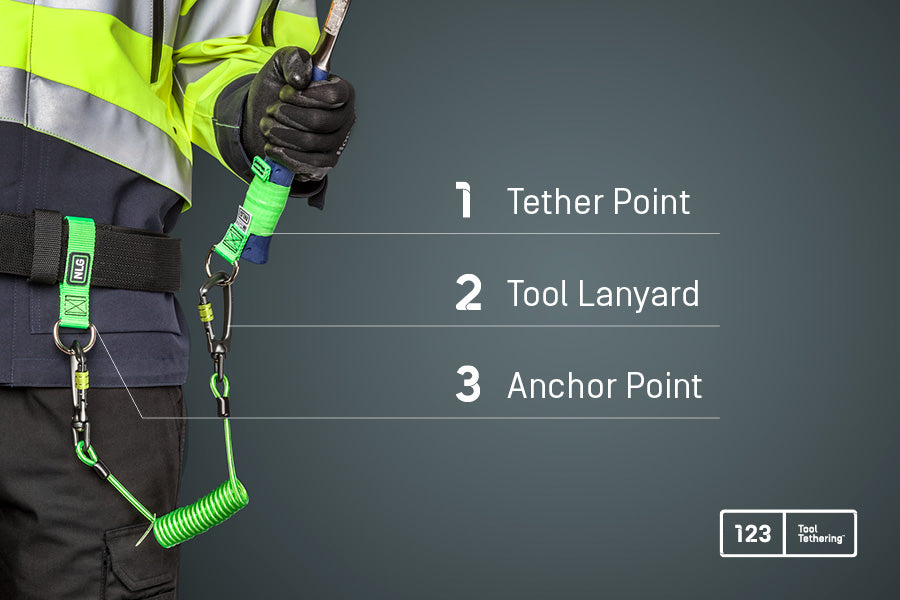

A typical tool tethering system will have three parts: the tether point on the tool itself, a tool lanyard, and an anchor point. It’s what’s known as preventative control, in that it stops tools from falling or being dropped in the first place.

Many of the steps currently taken to mitigate the risk of falling objects are secondary measures. They don’t stop tools from falling, but instead try to reduce the damage they cause when they do. They include wearing hard hats on building sites, as well as the use of netting, toe boards and edge protection.

Tool tethering is different. It gets to the root of the problem and stops drops before they cause an incident.

Why tether your tools?

With the likes of netting, toe boards, exclusion zones and PPE common in many sectors, you might be wondering why you should add tethering to the list of health and safety procedures.

Here’s why:

Firstly, these measures don’t do nearly enough to prevent injuries and fatalities. In fact, dropped objects are the third largest cause of workplace fatalities around the world.

Dropped objects are the third largest cause of workplace fatalities around the world.

From a human perspective, the cost of dropped tools or other objects is incalculable. It costs people lives. It can lead to life-changing injuries. Even those who aren’t hit by the object can be psychologically affected by an incident.

From a business perspective, there are financial costs to consider. Falling objects can cause damage to other surfaces or pieces of equipment. Dropped tools themselves may be damaged beyond repair. If someone is hit by a falling object, the cost of compensation and legal fees can be substantial.

There’s also the reputational damage this causes. A serious injury or death caused by a dropped object can be difficult for a business to recover from.

Dropped tools also equate to lost time and productivity. If workers have to retrieve items from several floors down, it can take considerably longer for them to complete their work. If the tool they’ve dropped is irreparably damaged, they may not be able to complete the job at all.

The other reason to tether tools is that the protective measures in place don’t do enough. Impact forces from even small objects can be considerable if they’re dropped from a great enough height. That means a hard hat may not provide sufficient protection.

We can hear you thinking, but what about exclusion zones? Don’t they cover us?

Not exactly.

Although exclusion zones are a common way of dealing with the risk of dropped objects, they don’t allow for deflections. A falling object can change course and fly hundreds of feet in a random direction. It becomes a projectile and poses a serious risk to other workers as well as members of the public.

Industries and governments around the world are beginning to realise the need to do more to prevent dropped objects. As a result, new regulations and guidance are being introduced to ensure more businesses tackle the problem of dropped objects head-on.

How to tether tools

Tethering tools can, quite literally, be as easy as one, two, three. We talked earlier about the three components of a tool tethering system:

1. Tether point

2. Tool lanyard

3. Anchor point

We’ve kept our tool tethering system simple because it doesn’t need to be more complicated than this.

Here are the three components:

Tether point

You need to begin with a tether point on the tool itself. As many tools don’t have an attachment point for a tool lanyard, we’ve developed tether points that can be retrofitted to any tool without causing damage, limiting its use or invalidating the tool’s warranty.

Create a tether point →

Tool lanyard

There are different types of tool lanyards for different equipment, tasks and environments. A tool lanyard can be made of webbing, wire or non-conductive materials. There are also bungee, coiled or retractable tool lanyard designs. You need to assess both your tools and where they’ll be used to decide which kind of lanyard is most suitable. You may want to have several types and lengths of lanyards to allow you to use your tools in various scenarios without any difficulty.

Choose the best tool lanyard →

Anchor point

Your anchor point needs to be just as robust as the rest of the system. For lighter tools, they can be secured to a wristband, a workbelt or to a harness worn by the worker. Heavier items should be tethered to a strong, fixed point such as a load rated rail or beam.

Select an anchor point →

Always remember that your tool tethering system is only as strong as its weakest point.

Safety standards

You need to ensure that your tool lanyard meets the minimum standards for safety. When you’re choosing a lanyard, there are a few things that you need to look for:

The first, and most important, is its load rating. Every tool lanyard should have a published capacity, i.e. be clearly marked with the safe working load. If a tool lanyard doesn’t have this, don’t use it. Your tool should weigh no more than the maximum load rating.

Ensure that your tool lanyards meet the minimum standards for safety.

NLG tool lanyards and tether points are rigorously tested by an independent third-party test laboratory, at a 2:1 safety factor (which means they are tested with twice the load they are marked with). That way you can be confident that each tool lanyard meets the load rating they’re marked with.

The length of your tool lanyard – and whether it’s a bungee, coiled or retractable tool lanyard – should also be determined by where you’re working, who else is working below you, and what tasks you’ll be completing. It is always considered best practice to select the shortest lanyard that is practical for the task as this will reduce the load force generated in the event of a drop.

In Europe, you should also look for a CE mark on any tool tethering system and a EU Certificate of Conformity. For the United States, the ANSI ISEA 121 Standard sets out certain specific criteria for tool tethering and all compliant equipment will carry the ANSI ISEA 121:2018 text. These marks show that the tool tethering equipment complies with the relevant safety requirements.

All safety equipment for dropped objects prevention should also be clearly marked with a serial number to allow for the proper identification and inspection recording. It is also recommended that tool lanyards and tethers are made from highly visible materials as it makes visual compliance checks easier for safety managers when they are reviewing operations.

You should be able to easily and quickly distinguish between any tool tethering equipment and fall arrest equipment. Most tool lanyards available on the market today are clearly marked ‘for tool use only’, but any that do not show this should be avoided as it could lead to confusion in choosing the correct equipment when working at height.

What are the tool tethering regulations?

What country you’re in will make a difference to what regulations are in place regarding tool tethering. We’ve broken it down into five common locations.

UK

The UK’s Working at Height Regulation 2005 clearly states “every employer shall, where necessary to prevent injury to any person, take suitable and sufficient steps to prevent, so far as is reasonably practicable, the fall of any material or object.” Whilst it requires companies to take “suitable and sufficient steps” to prevent objects or materials from falling, there is no explicit mention of tool tethering.

However, it’s easy to see how tool tethering would be classed as a suitable and sufficient step.

Exclusion zones are a secondary step within the regulations. That means failing to tether tools could still land you in trouble even if you’ve taken other precautions to prevent people from being hit by dropped objects.

But this ambiguity means that not all businesses in the UK adopt tool tethering when they have people working at height. This is changing though, as more and more progressive safety professionals are rejecting the uncertainty and exposure of dropped object risks and choosing to proactively manage them.

USA

In the US, the International Safety Equipment Association (ISEA) and the American National Standards Institute (ANSI) have approved and published a Dropped Objects Standard.

ANSI/ISEA 121-2018 American National Standard for Dropped Object Prevention Solutions has been developed in conjunction with industry as well as health and safety officials. It sets out minimum design, performance and labelling requirements for tethering solutions. It also details guidance for testing those products.

ANSI/ISEA 121-2018 sets out minimum design, performance and labelling requirements for tool tethering.

However, it doesn’t cover the proper use of tool tethering systems, specify what should be tethered, or when items need to be tethered. The ANSI/ISEA 121-2018 is also a voluntary consensus standard for this kind of equipment. That means it’s not an official health and safety regulation. But it is a basis for best practice and the majority of health and safety regulations around the world will cite best practice as the best way to interpret their regulations.

Canada

Canada’s Occupational Safety and Health Regulations give various examples of systems to manage and give protection from falling objects.

As you can learn in the Dropped Objects Prevention Handbook, they are examples of mitigating controls.

Brazil

In Brazil, the terminology is slightly different, but their Ministry of Labor and Employment clearly states “using tools with mooring to prevent their accidental fall”.

Australia

In Australia, dropped object legislation was introduced in the Work Health and Safety Regulations 2011. The government took these steps because of worrying statistics relating to injuries and deaths caused by falling objects.

The regulations state that any business that’s working at height must “manage risks to health and safety associated with an object falling on a person if the falling object is reasonably likely to injure the person”.

As we discussed earlier, even small objects can cause serious injuries. But like the UK legislation, there’s no specific mention of tool tethering within the guidance. That means that, in some cases, adequate measures aren’t currently being taken.

Tool tethering training

When you’re introducing new health and safety practices, regardless of the industry you’re in, one of the hardest parts is getting buy-in from your employees. They need to positively engage with the systems you implement to give them the best chance of succeeding.

Each individual needs to be responsible for the tethering of their tools. It’s not practical to have safety officers inspecting each operatives’ tethering system every day. The best way to get people to embrace a new safety initiative is with thorough training.

It’s important to change people’s perspectives when it comes to dropped objects. You need to develop a culture of awareness that encourages people to see the risks and take appropriate steps to manage them.

Explaining the damage and disruption dropped objects cause is a natural starting point. Highlight the human element and stress that a dropped object could injure or kill anyone. Tool tethering toolbox talks, as well as posters and information boards around your site, can act as reminders of the importance of tool tethering.

Large companies should look at how they share their tool tethering policies.

Large companies should look at how they share this information with their contractors, and at what steps they can take to ensure they always comply with best practice procedures in this area.

How to roll out a tool tethering system

Your journey to Zero Drops may be easier than you think. Here’s how you can get started:

You need to begin with a plan that’s designed not only for your industry, but for your site. This will be very specific and allow you to prepare for every eventuality.

Once you have your plan, you need to raise awareness among your workers so that they understand the dangers of dropped objects. This is where a strong training programme and toolbox talks will come in. It should cover why tools should be tethered as well as how to safely tether tools.

You will also want a tool tethering policy document, which outlines your minimum requirements and the objectives of your drop prevention plan. This can be shared with your supply chain so that there are consistent standards across each asset and site.

Before you roll it out to everyone, begin with a trial. Sharing the results of this trial is a great way to create buy-in across the rest of your organisation and make the full-scale rollout easier. It can alleviate any worries your team have about the new system or how its use could impact their own specific tasks.